Smash Repair House is a unique inner-city home built within the shell of a former automotive workshop in Paddington, Sydney. Behind its modest brick façade lies a calm, light-filled retreat, thoughtfully constructed to feel private, warm, and deeply connected to natural materials.

This was a complex and highly detailed build, requiring careful coordination to retain the original structure while creating a completely new interior experience. Our team worked closely with Matt Elkan to deliver a home that balances craftsmanship with restraint, featuring rich natural materials, layered finishes, and seamless transitions between indoor and outdoor spaces.

At the heart of the home is a central courtyard, bringing light and air across all three levels. Every element was built with precision and care, from the warm timber detailing to the robust steelwork. The result is a space that feels grounded, private, and timeless. An excellent example of how high-quality construction can transform a challenging site into a refined and livable home.

Type

Alterations and Additions

Architect

Matt Elkan

Engineer

SDA Structure

Photography

Clinton Weaver

Section DD

An abundance of ventilation through the Northern casement windows.

01

Stunning view of the Sydney skyline.

02

Polished concrete flooring.

03

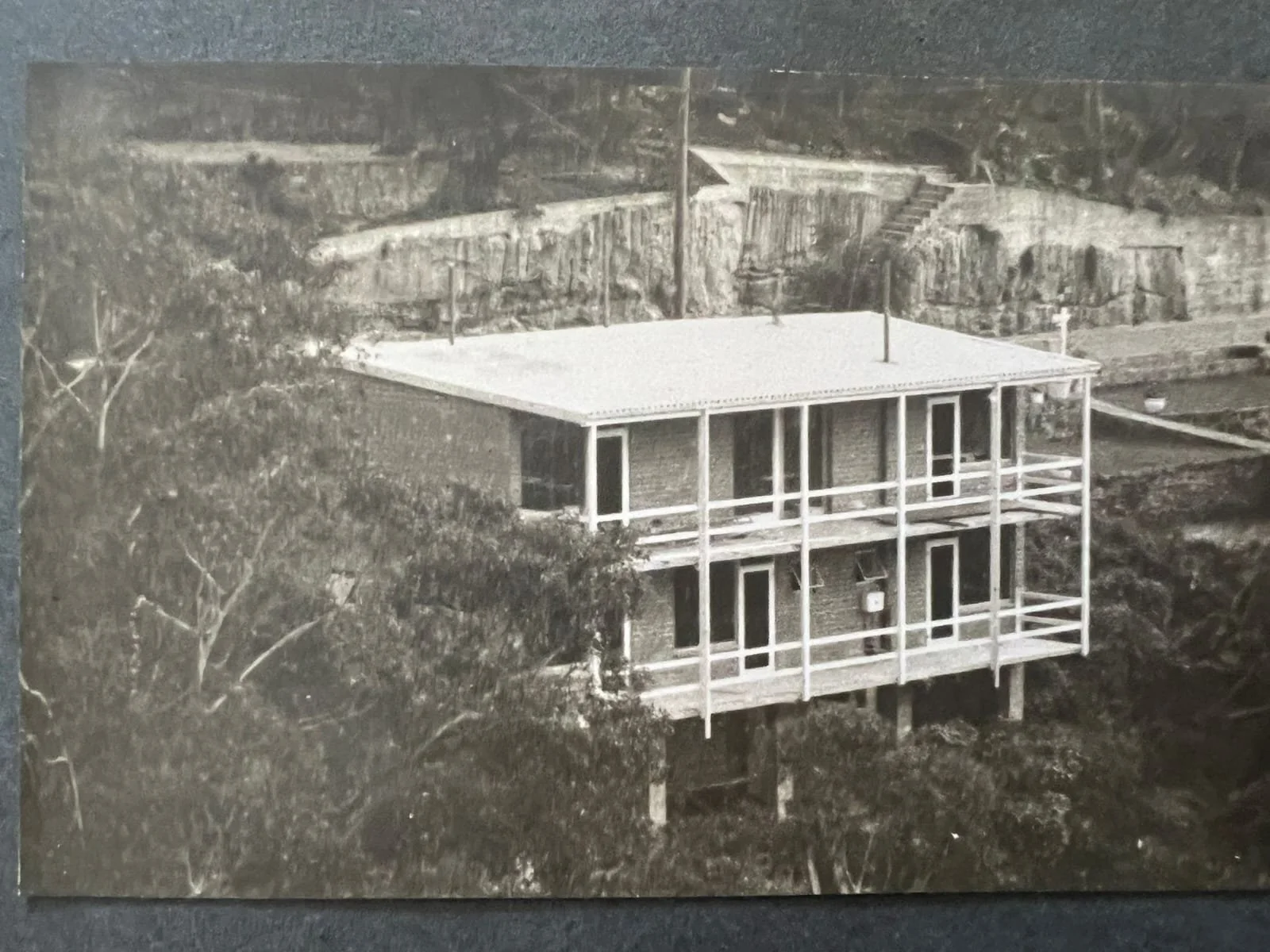

Northern elevation.

04

Exposed riser switchback stair case.

05

Direct sunlight enriching the Dining/Living through the skylight.

06

Courtyard view of the TV area.

07

Metal balustrade with timber handrail.

08

Street view of FF deck and pot plants.

09

Timber batten ceiling lining.

10

External masonry render.

11

Draped House slots between an existing scribbly gum tree.

12

Internal borrowed light louvre window.

13

Matt Elkan

Architect

“Delivered a beautiful project with clear and transparent communication , with absolute attention to detail.”

Our Impact

Adaptive Reuse and Heritage Integration

Transforming a former car workshop into a serene residence within a heritage conservation area, the project retained approximately 90% of the original brick perimeter walls. This approach preserved the site's historical character while introducing a new, introspective living space.

Sustainable Materials

The design prioritised sustainability by extensively using recycled and responsibly sourced materials. Reclaimed bricks and blackbutt timber featured prominently in floors, joinery, ceilings, and window frames. Additionally, salvaged hardwood from the site was repurposed into furniture pieces, exemplifying a commitment to material reuse.

Environmental Performance

The home's layout centers around a private courtyard, facilitating natural light penetration and cross-ventilation across all three levels. Operable screens and internal shutters made from recycled blackbutt timber provide adjustable shading and privacy, enhancing thermal comfort without reliance on mechanical systems.

Craftsmanship and Acoustic Considerations

Attention to detail is evident in the open-jointed blackbutt battened ceilings, which not only contribute to the home's aesthetic warmth but also serve an acoustic function by absorbing reflected sound. This meticulous craftsmanship ensures a tranquil and harmonious interior environment.

Our Process

Pre-Construction

1

Being our fourth project on this tight one-way street, and the first positioned on a corner opposite a major arterial road, this site required heightened coordination. With limited street access and constrained material drop zones, careful planning was essential to keep the build flowing. Early engagement with the architect, consultants, and key subcontractors helped refine sequencing and mitigate risk. Through a mix of value engineering and site-specific planning, we ensured the design could be delivered with minimal disruption to the neighbours, and to the busy surrounding street network.

Early Consultation to Refine Access, Staging, and Buildability

Detailed Site Planning for Tight one-way Street Corner with High Traffic

Key Subcontractors Engaged early to Align Sequencing and Minimise Disruption

Early Works

2

Early works required surgical precision. With no off-street parking and limited access on a one-way street, demolition was staged and coordinated to maintain site safety and retain the existing perimeter walls. Structural bracing supported elements to be kept, while hazardous materials were safely removed and salvageable bricks, timber, and fittings were stored for reuse. The new concrete slab was poured between the original walls, anchoring the future works with minimal tolerance and maximum control.

Tight Access Resolved Through Staged Demolition and Boundary Bracing.

Existing Walls and Frame Retained with Careful Sequencing.

No Site Parking. Logistics Coordinated to the Minute.

Structure

3

A complex double brick build supported internally by a timber structure with zero tolerance demands. Recycled blackbutt was used throughout, particularly where structure remained exposed and aligned with full-height openings. The perimeter walls and sections of the slab were retained, requiring careful integration between new and existing elements. Temporary propping was used to support the upper floor during framing, while recycled brickwork was reintroduced with precision across the new form.

Predominantly Timber-Framed with Exposed Structural Alignment

Enclosure

4

The envelope balances performance, texture, and restraint. Bagged recycled brickwork grounds the house in its heritage context, while fibre cement cladding lines the courtyard-facing elevations. High-performance membranes, insulation, and detailing deliver thermal performance and airtightness. Recycled Australian hardwood doors and windows, all double glazed, deliver thermal performance and character, with crisp alignments and refined interfaces ensuring precision throughout

Recycled Hardwood Doors and Windows, all Double Glazed for Acoustic and Thermal Performance

Fibre Cement Cladding Installed over High-Performance Membranes and Insulation

Bagged Recycled Brickwork, Heritage Galvanised Detailing, and Resolved Junctions across Material Transitions

Interiors

5

The interior fitout was carefully coordinated to ensure performance, durability, and visual clarity. Heating and cooling systems were integrated early, with in-slab hydronic heating to the ground floor and concealed ceiling systems above, delivering year-round comfort without compromise. Services and plant were planned from the outset to be fully concealed, allowing for clean detailing and reduced visual clutter.

Solid timber floors and custom spotted gum joinery provide warmth and longevity. All finishes were executed with minimal trims, no skirtings or architraves, demandig zero tolerance and exact setouts. Tiling was planned in coordination with cabinetry and structure to ensure alignment. External elements like wire balustrades, brick paving, and recycled hardwood were carried inside to maintain consistency and quality throughout the home.

Hydronic Heating in the Ground Floor Topping Slab, Concealed HVAC, the same External Doors Quality Doors used Internally

Hardwood Ceiling Battens throughout, Blackbutt Flooring, Joinery, Structure, Furniture

Aftercare

6

Our involvement didn’t end at handover. We’ve continued to support the client through seasonal maintenance, fine-tuning details, and ongoing care of materials. From timber oiling to small service callouts and custom additions, we help keep the home functioning beautifully.

Routine Timber Maintenance and Surface Reconditioning