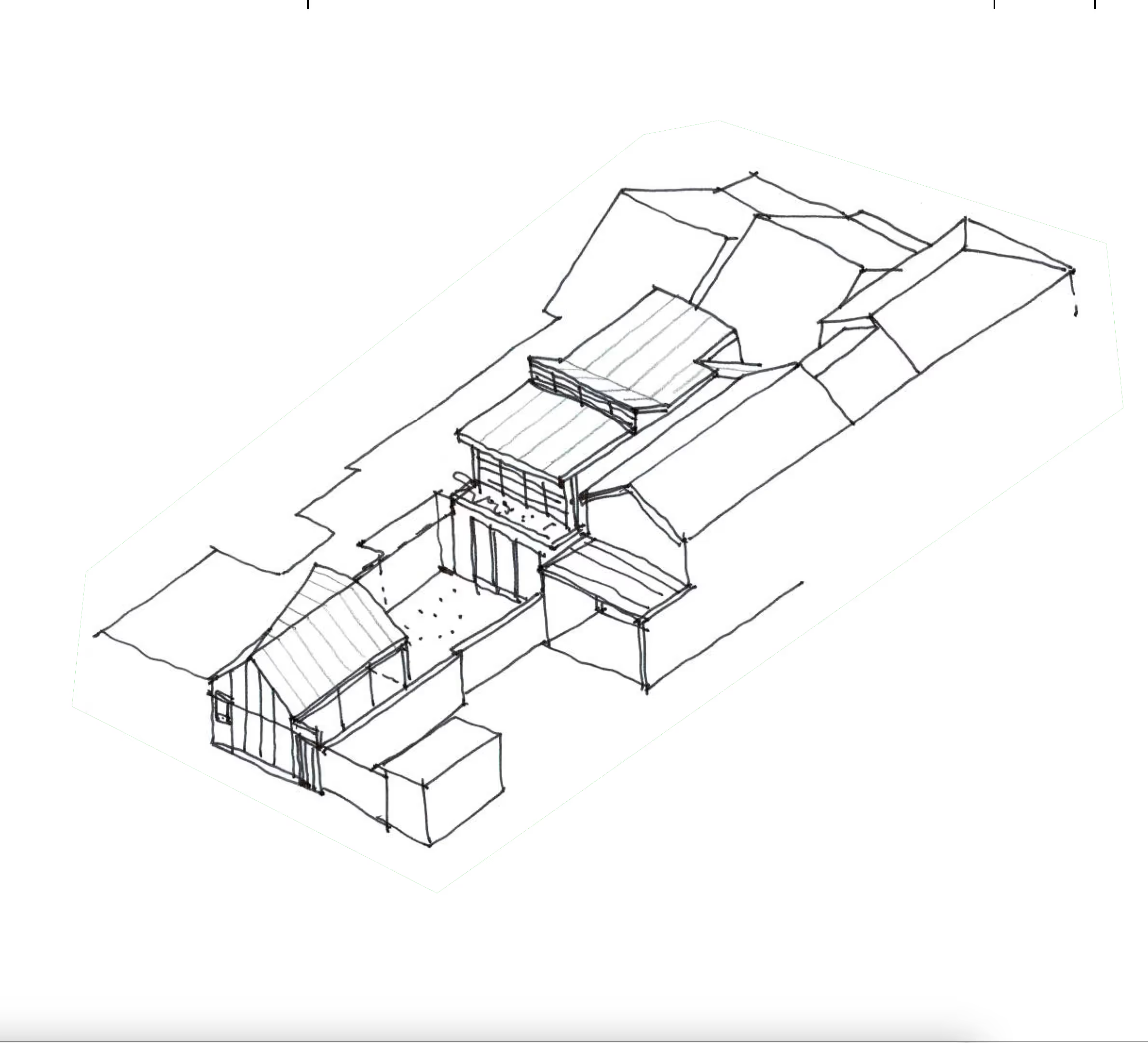

CLT Cottage is a compact but technically demanding addition and secondary dwelling to a heritage home in Sydney’s inner west. Delivered during the height of the COVID lockdowns on a narrow laneway site with limited access and a complex roof form.

We were brought on early and worked closely with the architect to put forward a CLT-led approach that would keep the program tight, provide supply certainty, and deliver a high-performance outcome within budget.

As timber specialists, we saw CLT as the right method for the job offering precision, structural efficiency, and a natural finish with low embodied carbon. Preclad, prefabricated panels meant we went from slab to watertight in under a week.

We planned crane access, sequenced deliveries, and managed tolerances to the millimetre. From sequencing to structure, it was a project that rewarded preparation.

Type

Alterations and Additions

Architect

Still Space Architecture

Engineer

Sellick Consultants

Photography

Brett Broadman

Section A

CLT panels - both structure and interior lining.

01

The double height studio from the rear laneway.

02

Laneway entry.

03

07

Translucent cladding keeps the studio light.

04

First floor of the rear studio

05

Open plan kitchen and living

06

Our Impact

Responsible Material Use

We chose locally manufactured, PEFC/Responsible Wood‑certified CLT panels engineered from fast growth plantation pine and precision CNC‑cut to size. This choice locks carbon into the structure significantly lowers embodied emissions compared to steel or concrete , and creates minimal on‑site waste due to factory precision .

High-Performance Envelope

The CLT structure forms a robust, continuous enclosure with excellent airtightness and acoustic performance. While not highly insulative on its own, its thermal mass contributes to a stable internal environment when combined with external insulation. The result is a comfortable, low-energy building shell designed for long-term performance.

Site Efficiency

Prefabricated CLT panels and precision CNC detailing allowed us to go from slab to watertight within weeks. Lightweight panels (just ~20% the weight of steel & concrete) sped up the build schedule, reduced neighbour disruption, and improved site safety, all while maintaining precise tolerances

Integrated Structure + Finish

The exposed CLT structure serves triple duty as structure, lining, and finish — eliminating the need for additional framing, linings, or decorative treatments. This integrated approach reduces material layers, simplifies detailing, and showcases the natural beauty of timber.

Our Process

Pre-Construction

1

Working closely with Still Space Architecture, we engaged early in the design process to shape a buildable, efficient outcome. Our team supported approvals with traffic, waste, and hazardous material reports, explored a range of construction methodologies, programs, and budgets, and ultimately landed on CLT for its efficiency, sustainability, and precision. The decision enabled early coordination, reduced site time, and aligned with the project’s environmental goals

Progressive pricing aligned to design phases

Early design coordination, proposed CLT construction methodology

Site inspections to assess buildability, tolerances, and access

Early Works

2

The early works phase combined careful deconstruction with complex site preparation. Salvaged materials were set aside for reuse, while underpinning and propping strategies protected both the neighbouring party wall and the existing heritage cottage. Excavation for the 10,000L underground water tank was strategically sequenced between the extension and second dwelling concrete pours..

Deconstruction for material salvage and reuse

Underpinning and propping of adjoining party wall and heritage cottage

Excavation of 10,000L underground water tank