Cloaked House was a test of precision, sequencing, and trust. Perched on a steep, land-slip-prone site in Mosman, the project involved retaining and remediating the existing mid-century structure while excavating a new basement beneath it, all without compromising its integrity. From stabilising the hillside to removing asbestos and treating concrete cancer, early works were carried out with care and foresight.

A new insulated timber skin was wrapped around the original blockwork, dramatically improving passive performance without the need to demolish and rebuild. Structural steel was retained, stitched into, and extended with timber and recycled Australian hardwoods, allowing for new services and high-performance glazing. Much of the home was built from within, requiring close coordination, careful access planning, and a collaborative approach from every trade.

Rather than starting over, we enhanced what was already there, extending the life, performance, and story of an existing home. This is what we mean by craftsmanship and care.

Type

Extensive Structural Remediation, Renovation & Landscaping

Architect

Trias

Engineer

Clinton Weaver

Photography

Clinton Weaver

Section A

Open riser staircase in the central courtyard.

01

The handing pendent lights and ceiling rafters pay homage to the original design of the home.

02

Polished concrete floors in the downstairs living room.

03

Large solid entry door.

04

Redesign of the timber and steel balconies.

05

Australian hardwood joinery and green tiles that give reference to the midcentry era of the home.

06

Curved sheer curtain to seperate the entry and upstairs living.

07

Recycled timber floorboards.

08

Eastern elevation of the balconies with Abodo stained timber cladding

09

Sliding doors pull back to connect the balconies to internal areas.

10

Openings are enlarged for light, air and view.

11

Full view of the rear of the home.

12

Recycled mosaic tiles and square cabinets call back to the homes original design.

13

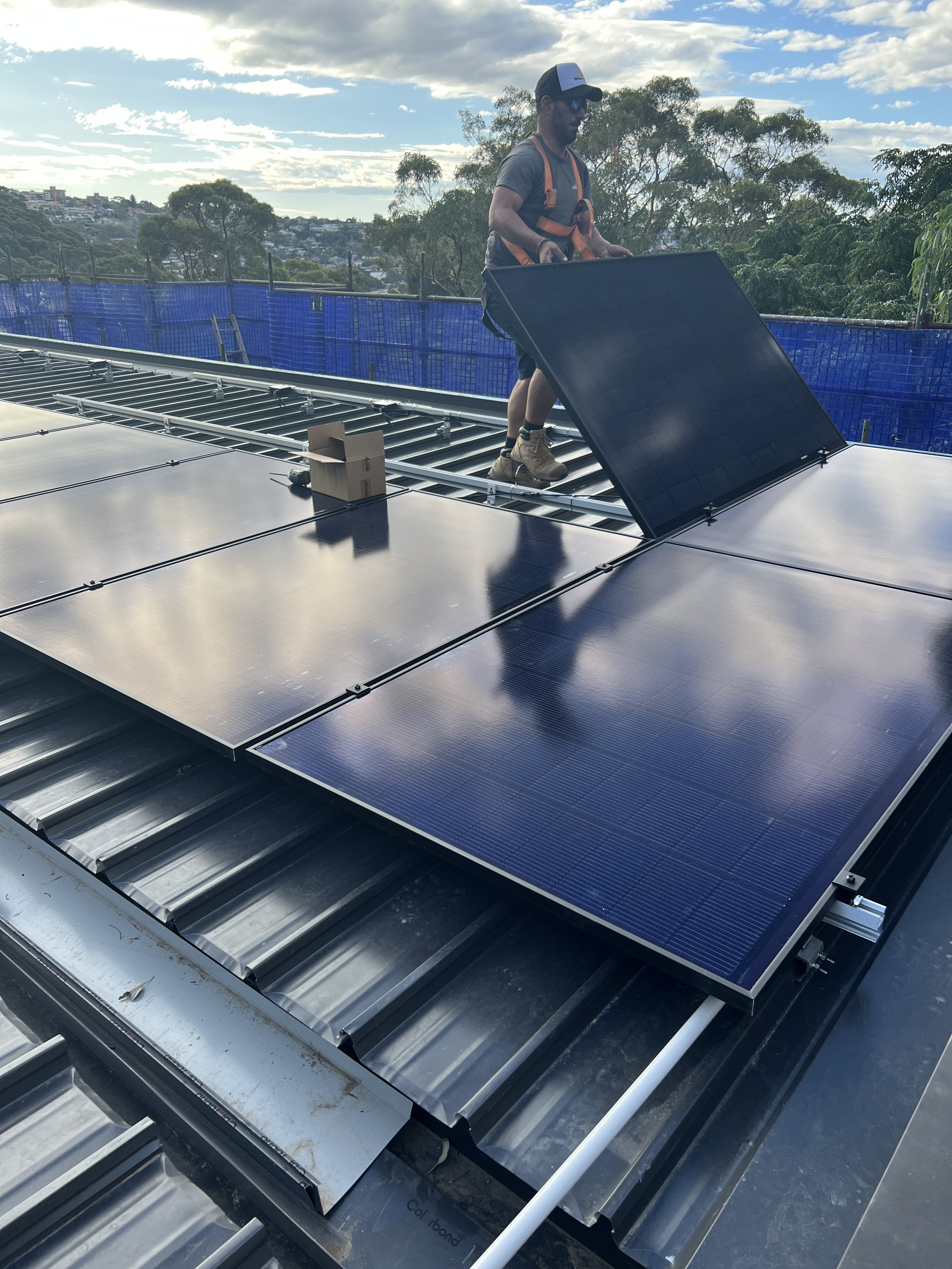

Our Impact

Working With the Landscape

We preserved three mature gum trees and followed the site’s natural topography by stepping the house with the slope. Minimal excavation was required, a coordinated approach that respected the land and reduced intervention..

Built to Last

We used compressed fibre cement sheeting for the external cladding, selected for its durability, fire resistance, and low-maintenance performance in exposed conditions. Fixings and junctions were detailed and executed to last.

Material Decisions That Matter

Double-glazed doors were fabricated using reclaimed Australian hardwoods. Salvaged in partnership with the architect, these were refinished and repurposed to deliver warmth, character, and performance, extending the life of materials that would otherwise be lost.

Reuse with Intention

A predominantly timber structure was sourced locally and pre-cut offsite before slab pour. This reduced on-site construction time, minimised waste, and lowered transport-related emissions.

Recycled Hardwood Joinery integrated into the Abodo cladding with operable hatches and windows for ventilation, shading, and performance.

Structural Timber posts extended three floors high supporting all the balconies, balustrades and roof.

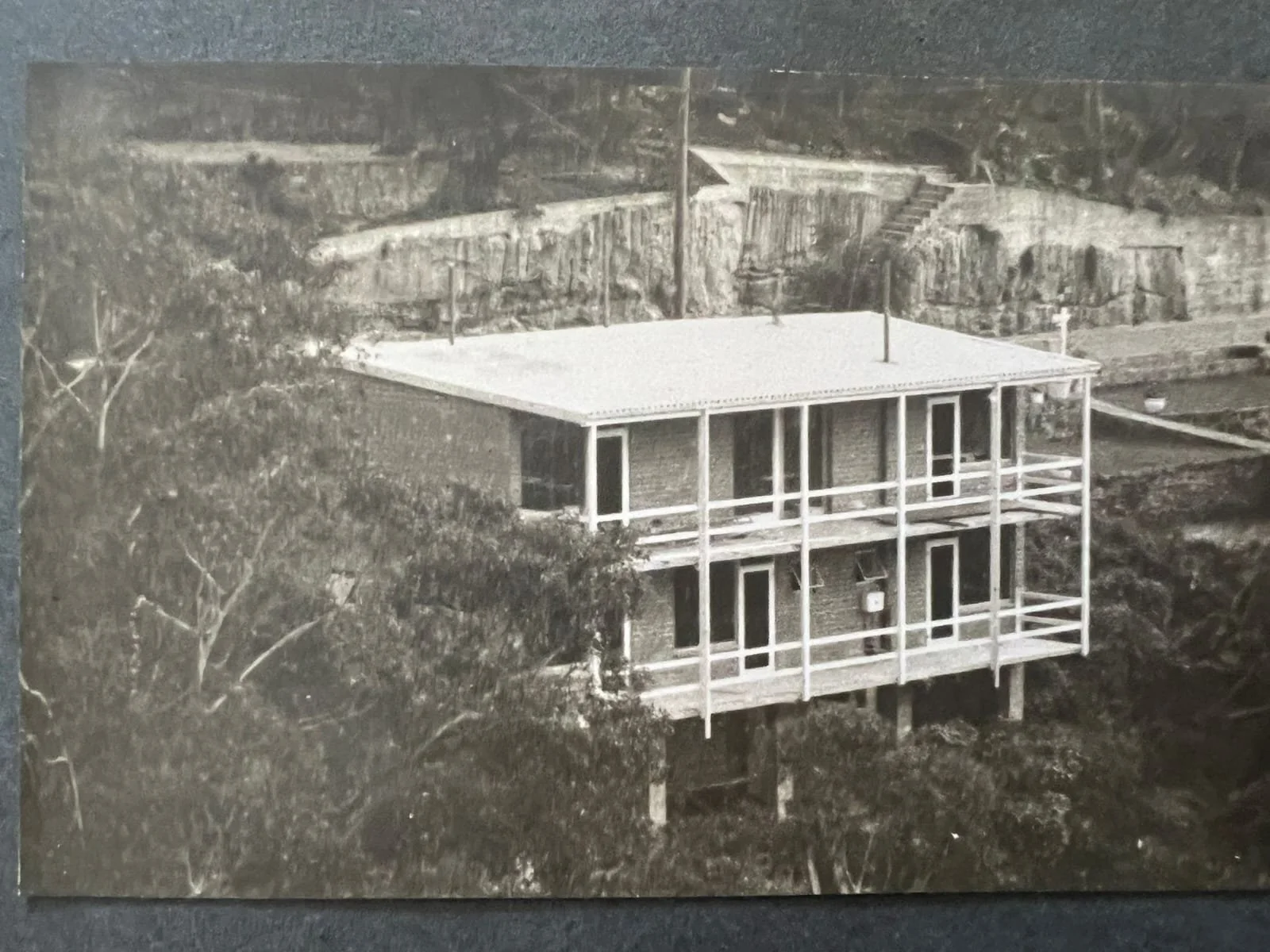

Original Photo taken in 1960.

Kitchen tiles micro adjustment to joinery and structure to ensure a full tile bench and splashback.

Initial design model by Trias.

Our Process

Pre-Construction

1

In addition to progressive preliminary pricing, pre-construction focused on understanding the existing structure, determining how best to remove, retain, reinforce, and support it. Key trades were brought in early to ensure the build was achievable on a steep, land-slip-prone site. We worked closely with the architect and engineer to cost design options, refine sequencing, and value manage key packages, aligning architectural outcomes with program, access, and budget realities.

Initial design model by Trias.

Progressive preliminary pricing and design option

Site inspections to assess structure, buildability, and sequencing

Early sub-contractor involvement to inform program and methods

Kitchen tiles micro adjustment to joinery and structure to ensure a full tile bench and splashback.

Early Works

2

Early works were extensive; stabilising the land, remediating the structure, and preparing for excavation beneath the existing house. Works included piling, shotcrete, and major earthworks through sandstone to carve out a new basement. Tree protection, asbestos removal, and treatment of concrete cancer were undertaken with care, alongside the safe removal of original balconies and other compromised elements.

Land stabilisation, piling, and shotcrete to secure steep site

Subterranean excavation through rock for a new basement beneath the existing home

Remediation of concrete cancer, asbestos removal, and forensic demolition

Shotcrete Stabilisation to retain the existing site conditions

Structure

3

The existing structural skeleton slabs steel and perimeter blockwork was retained and remediated, becoming the backbone for the new works. Careful propping and sequencing allowed us to insert new framing and infill without disturbing the structure’s integrity. Timber was used strategically to introduce warmth, lighten loads, and ensure buildability on a constrained site. Much of the new work was stitched directly into the old requiring high precision and close coordination between trades.

Timber framing and posts strengthen, allow for new services and insulation while reducing structural load

Retained super structure formed the foundation for the new works

Sequencing, propping and remedial works ensured safe integration of new structure within the retained envelope

Temporary Void during temporary propping and infilling of perimeter walls

Enclosure

4

A new timber-framed skin was built around the existing block structure, allowing for insulation to be installed continuously across the facade. This was then wrapped in high-performance membranes, tapes, and flashings to ensure airtightness and elevate passive performance. The cladding is rapid growth and thermally modified timber. Doors, windows, and ventilation hatches all double-glazed and made from recycled Australian hardwoods punctuate the enclosure with precision.

Abodo cladding installed over breathable membranes for long-term durability

Recycled Australian hardwoods used for all external joinery, double-glazed for acoustic and thermal performance

Insulated timber skin enables passive performance while retaining the original structure underneath

Insulated Timber Skin installed between new timber framing over the original blockwork, forming a continuous thermal envelope beneath the cladding.

Interiors

5

The interior fitout was carefully coordinated to ensure performance, durability, and visual clarity. Heating and cooling systems were integrated early, with in-slab hydronic heating to the ground floor and concealed ceiling systems above, delivering year-round comfort without compromise. Services and plant were planned from the outset to be fully concealed, allowing for clean detailing and reduced visual clutter.

Solid timber floors and custom spotted gum joinery provide warmth and longevity. All finishes were executed with minimal trims, no skirtings or architraves, demanding zero tolerance and exact setouts. Tiling was planned in coordination with cabinetry and structure to ensure alignment. External elements like wire balustrades, brick paving, and recycled hardwood were carried inside to maintain consistency and quality throughout the home.

Solid timber floors and spotted gum joinery for enduring quality

In-slab and in-ceiling hydronic systems installed for efficient, quiet thermal performance

We’ve also supported the clients in upgrading and expanding the house post-handover, providing trusted assistance for everything from new fixtures to EV infrastructure and a proposed pool addition ensuring continuity, care, and craftsmanship beyond completion.

Precision Execution steel, timber and block work coming together around the central atrium.

Aftercare

6

We've remained actively involved through seasonal and on-demand aftercare, from routine timber oiling, tile sealing, and repainting to coordinating services and trades. We’ve ensured fittings remain sound, systems operate smoothly, and the home continues to perform as intended. Our knowledge of the build allows us to provide fast, efficient care when needed, even as the home evolves.

Routine timber maintenance, stone sealing, and lanscape material top-ups

Precision Execution steel, timber and block work coming together around the central atrium.

Recognition

Awards

NSW Architecture Awards Accolades – Houses (Alterations and Additions)

Winner

Cloaked House

2025

NSW Architecture Awards Accolades – Houses (Alterations and Additions)

Winner

Cloaked House

2025

Publications

Master Builders Association - Excellence in Housing

Houses Magazine

Cloaked House

2025